Ready to learn Artificial Intelligence? Browse courses like Uncertain Knowledge and Reasoning in Artificial Intelligence developed by industry thought leaders and Experfy in Harvard Innovation Lab.

Let’s lay down some fundamentals. In business you want to achieve the highest revenues with the best margins and the lowest costs. More specifically, in manufacturing, you want your products to be the highest quality (relative to specification) when you make the item. And you want it shipped to the right place at the right time when planning your supply chain. And you want to achieve the best customer satisfaction when you engage with them and have as few returns or failures as possible while in service. Seems simple, right?

Most of us will have seen the tree swing cartoon below. It's been around for many years, but it's still an apt illustration of the importance of focus, data, insight and collaboration.

The level of complexity, speed and detail in modern manufacturing processes has become almost impossible to manage via manual or human effort alone. And that increases the risk of the many misunderstandings outlined above. Assistance from technology and engineering have been prevalent since the introduction of the steam engine, but as we navigate through the Fourth Industrial Revolution (Industry 4.0), artificial intelligence (AI) is becoming a common theme.

But let’s break this term down: Artificial means made by humans, especially in imitation of something natural. Intelligence is the ability to acquire and apply knowledge and skills. So we’ve been applying AI for quite a while, but now we’re applying it to computers.

AI in manufacturing

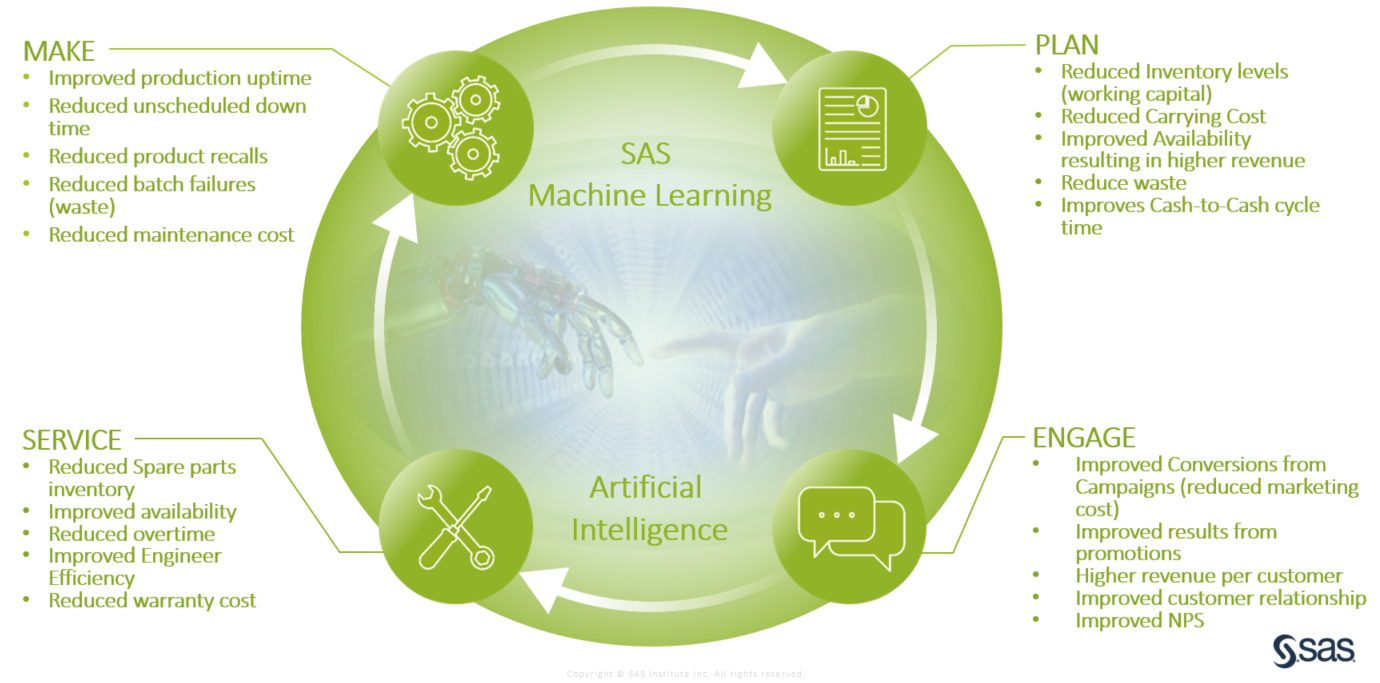

When we apply artificial intelligence or machine learning to the manufacturing process, what do we mean? For us at SAS, this is about understanding data, extracting insight and learning from the outputs. Analytics is about iteration and learning, and as we learn we change or influence the next step. This process can also be referred to as machine learning, meaning the machine carries out this iterative process without the need for human intervention.

The benefits of machine learning are wide and varied, and in the right hands can provide extensive value to your business through high levels of automation. Machine learning can identify previously unseen relationships and influence processes or data sets, and extract insights quicker and in more detail than ever before.

AI is already here and taking effect. The people and businesses that understand what it is and how it can help will prosper thanks to greater insight, agility and growth. Those that don’t will have to work harder and longer to compete.

Proven AI with proven results

Many software vendors claim AI, cognitive and machine learning capabilities. While some can provide these to some extent, the evolution of any technology shows the more you focus on it, invest and develop it, the better you are at it. SAS has done this for more than 40 years, and that's why we lead the pack in advanced analytics to support AI, cognitive and machine learning capabilities, according to Forrester and Gartner independent industry reviews.

SAS has taken its extensive knowledge and investments to harness the Power to Know into the manufacturing world. We've connected processes and capabilities around monitoring machines, systems and data in the make process, and can join this to post-production analysis around forecasting and supply chain processes to aid future planning. This is paired with data driven analytical approaches to customer engagement and post-sale monitoring of product performance, service requirements and infield product satisfaction. This process is illustrated below:

All successful businesses invest in operational platforms like ERP, finance and billing systems. More recently business have seen extensive value in productivity platforms with office tools and CRM systems. Now the next wave is here – analytical platforms that encompass AI and machine learning to support your organisation beyond the expected key performance indicators that are traditionally used.