Startups’ ambitious AI-based new product development is driving AI-related investment with $16.5B raised in 2019, driven by 695 deals according to PwC/CB Insights MoneyTree Report, Q1 2020.

From startups to enterprises racing to get new products launched, AI and machine learning (ML) are making solid contributions to accelerating new product development. There are 15,400 job positions for DevOps and product development engineers with AI and machine learning today on Indeed, LinkedIn and Monster combined. Capgemini predicts the size of the connected products market will range between $519B to $685B this year with AI and ML-enabled services revenue models becoming commonplace.

Rapid advances in AI-based apps, products and services will also force the consolidation of the IoT platform market. The IoT platform providers concentrating on business challenges in vertical markets stand the best chance of surviving the coming IoT platform shakeout. As AI and ML get more ingrained in new product development, the IoT platforms and ecosystems supporting smarter, more connected products need to make plans now how they’re going to keep up. Relying on technology alone, like many IoT platforms are today, isn’t going to be enough to keep up with the pace of change coming. The following are 10 ways AI is improving new product development today:

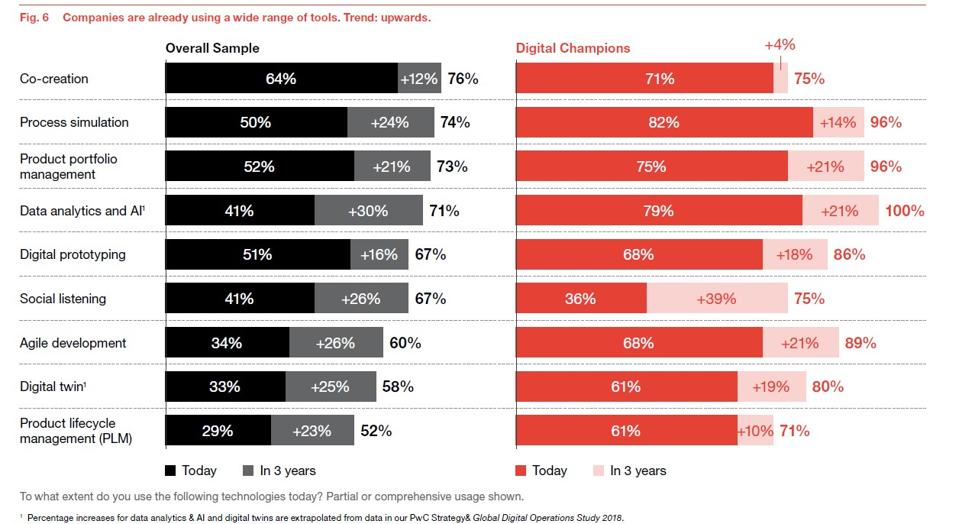

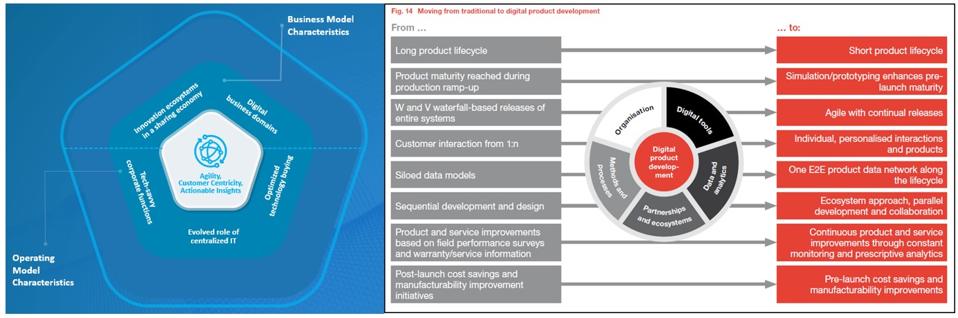

14% of enterprises who are the most advanced using AI and ML for new product development earn more than 30% of their revenues from fully digital products or services and lead their peers is successfully using nine key technologies and tools. PwC found that Digital Champions are significantly ahead in generating revenue from new products and services and more than a fifth of champions (29%) earn more than 30% of revenues from new products within two years of information. Digital Champions have high expectations for gaining greater benefits from personalization as well. The following graphic from Digital Product Development 2025: Agile, Collaborative, AI-Driven and Customer Centric, PwC, 2020 (PDF, 45 pp.) compares Digital Champions’ success with AI and ML-based new product development tools versus their peers:

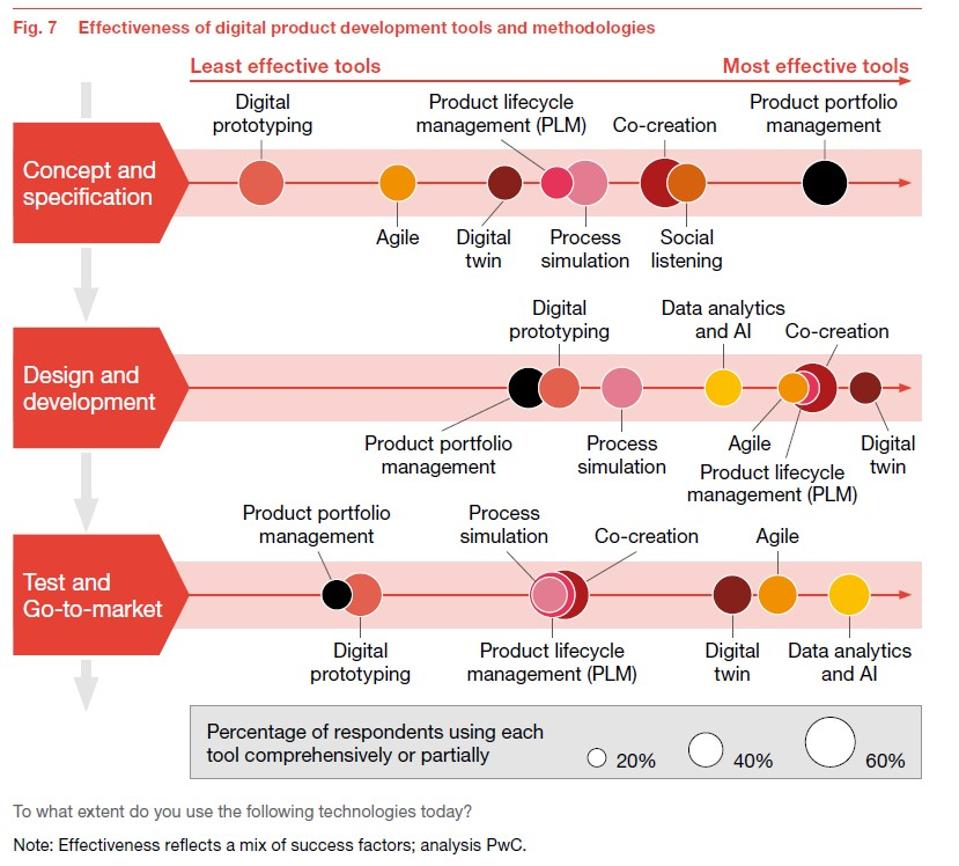

61% of enterprises who are the most advanced using AI and ML (Digital Champions) use fully integrated Product Lifecycle Management (PLM) systems compared to just 12% of organizations not using AI/ML today (Digital Novices). Product Development teams the most advanced in their use of AL & ML achieve greater economies of scale, efficiency and speed gains across the three core areas of development shown below. Digital Champions concentrate on gaining time-to-market and speed advantages in the areas of Digital Prototyping, PLM, co-creation of new products with customers, Product Portfolio Management and Data Analytics and AI adoption:

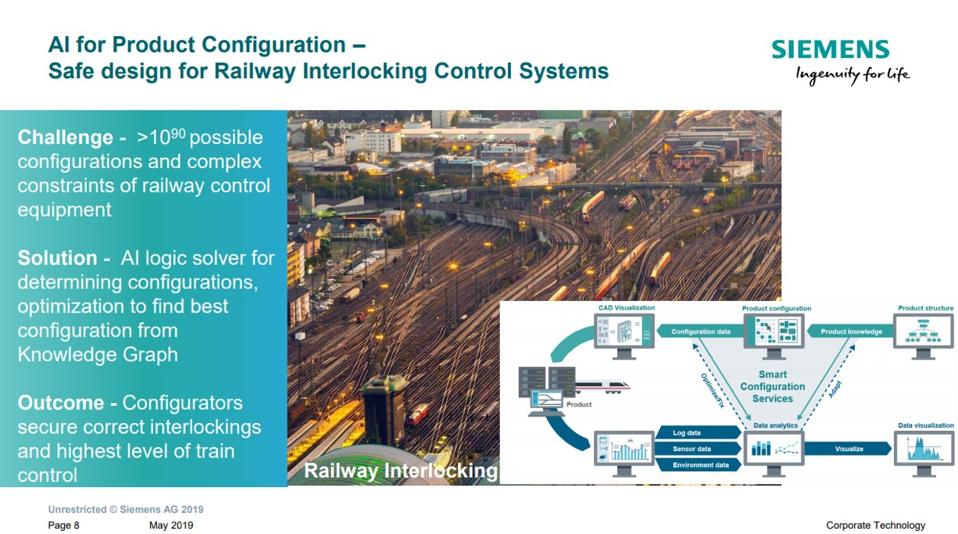

AI is actively being used in the planning, implementation and fine-tuning of interlocking railway equipment product lines and systems. Engineer-to-order product strategies introduce an exponential number of product, service and network options. Optimizing product configurations require an AI-based logic solver that can factor in all constraints and create a Knowledge Graph to guide deployment. Siemens’ approach to using AI to find the optimal configuration out of 10 90 possible combinations provides insights into how AI can help with new product development on a large scale. Source: Siemens, Next Level AI – Powered by Knowledge Graphs and Data Thinking, Siemens China Innovation Day, Michael May, Chengdu, May 15, 2019.

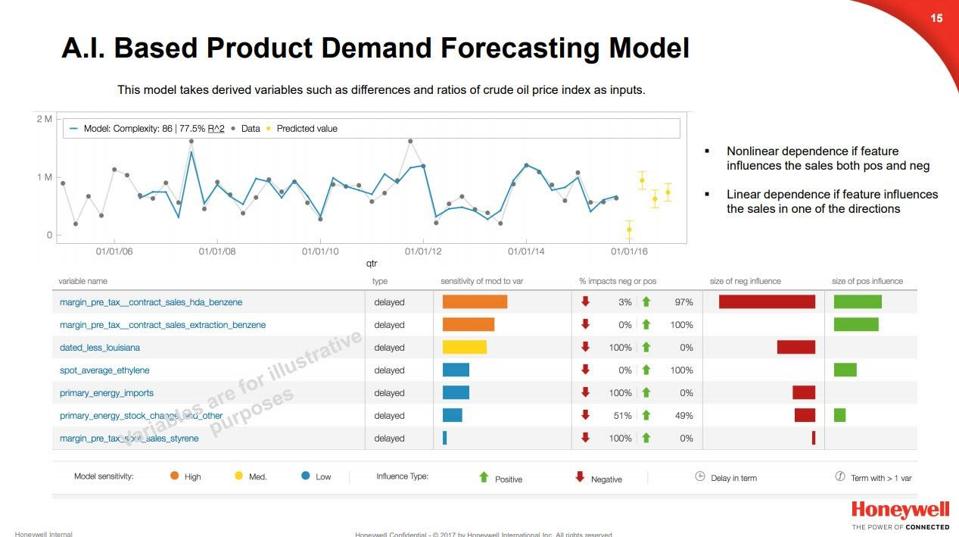

Eliminating the roadblocks to getting new products launched starts with using AI to improve demand forecast accuracy. Honeywell is using AI to reduce energy costs and negative price variance by tracking and analyzing price elasticity and price sensitivity as well. Honeywell is integrating AI and machine-learning algorithms into procurement, strategic sourcing and cost management getting solid returns across the new product development process. Source: Honeywell Connected Plant: Analytics and Beyond. (23 pp., PDF, no opt-in) 2017 Honeywell User’s Group.

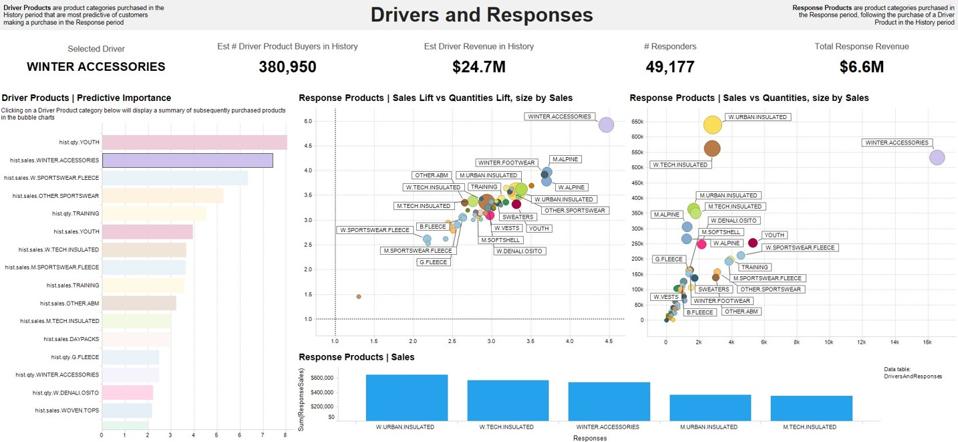

Relying on AI-based techniques to create and fine-tune propensity models that define product line extensions and add-on products that deliver the most profitable cross-sell and up-sell opportunities by product line, customer segment and persona. It’s common to find data-driven new product development and product management teams using propensity models to define the products and services with the highest probability of being purchased. Too often, propensity models are based on imported data, built-in Microsoft Excel, making their ongoing use time-consuming. AI is streamlining creation, fine-tuning and revenue contributions of up-sell and cross-sell strategies by automating the entire progress. The screen below is an example of a propensity model created in Microsoft Power BI.

AI is enabling the next generation of frameworks that reduce time-to-market while improving product quality and flexibility in meeting unique customization requirements on every customer order. AI is making it possible to synchronize better suppliers, engineering, DevOps, product management, marketing, pricing, sales and service to ensure a higher probability of a new product succeeding in the market. Leaders in this area include BMC’s Autonomous Digital Enterprise (ADE). BMC’s ADE framework shows the potential to deliver next-generation business models for growth-minded organizations looking to run and reinvent their businesses with AI/ML capabilities and deliver value with competitive differentiation enabled by agility, customer centricity and actionable insights. The ADE framework is capable of flexing and responding more quickly to customer requirements than competitive frameworks due to the following five factors: proven ability to deliver a transcendent customer experience; automated customer interactions and operations across distributed organizations; seeing enterprise DevOps as natural evolution of software DevOps; creating the foundation for a data-driven business that operates with a data mindset and analytical capabilities to enable new revenue streams; and a platform well-suited for adaptive cybersecurity. Taken together, BMC’s ADE framework is what the future of digitally-driven business frameworks look like that can scale to support AI-driven new product development. The following graphic compares the BMC ADE framework (left) and the eight factors driving digital product development as defined by PwC (right) through their extensive research. For more information on BMC’s ADE framework, please see BMC’s Autonomous Digital Enterprise site. For additional information on PwC’s research, please see the document Digital Product Development 2025: Agile, Collaborative, AI-Driven and Customer Centric, PwC, 2020 (PDF, 45 pp.).

Using AI to analyze and provide recommendations on how product usability can be improved continuously. It’s common for DevOps, engineering and product management to run A/B tests and multivariate tests to identify the usability features, workflows and app & service responses customers prefer. Based on personal experience, one of the most challenging aspects of new product development is designing an effective, engaging and intuitive user experience that turns usability into a strength for the product. When AI techniques are part of the core new product development cycle, including usability, delivering enjoyable customer experiences, becomes possible. Instead of a new app, service, or device is a chore to use, AI can provide insights to make the experience intuitive and even fun.

- Forecasting demand for new products, including the causal factors that most drive new sales is an area AI is being applied to today with strong results. From the pragmatic approaches of asking channel partners, indirect and direct sales teams, how many of a new product they will sell to using advanced statistical models, there is a wide variation in how companies forecast demand for a next-generation product. AI and ML are proving to be valuable at taking into account causal factors that influence demand yet had not been known of before.

- Designing the next generation of Nissan vehicles using AI is streamlining new product development, trimming weeks off new vehicle development schedules. Nissan’s pilot program for using AI to fast-track new vehicle designs is called DriveSpark. It was launched in 2016 as an experimental program and has since proven valuable for accelerating new vehicle development while ensuring compliance and regulatory requirements are met. They’ve also used AI to extend the lifecycles of existing models as well. For more information, see the article, DriveSpark, “Nissan’s Idea: Let An Artificial Intelligence Design Our Cars,” September 2016.

- Using generative design algorithms that rely on machine learning techniques to factor in design constraints and provide an optimized product design. Having constraint-optimizing logic within a CAD design environment helps GM attain the goal of rapid prototyping. Designers provide definitions of the functional requirements, materials, manufacturing methods and other constraints. In May 2018, General Motors adopted Autodesk generative design software to optimize for weight and other key product criteria essential for the parts being designed to succeed with additive manufacturing. The solution was recently tested with the prototyping of a seatbelt bracket part, which resulted in a single-piece design that is 40% lighter and 20% stronger than the original eight component design. Please see the Harvard Business School case analysis, Project Dreamcatcher: Can Generative Design Accelerate Additive Manufacturing? for additional information.

Additional reading:

Accenture, Manufacturing The Future, Artificial intelligence will fuel the next wave of growth for industrial equipment companies (PDF, 20 pp., no opt-in)

AI Priorities February 2020 5 ways to go from reality check to real-world pay off, PwC, February, 2020 (PDF, 16 pp.)

Anderson, M. (2019). Machine learning in manufacturing. Automotive Design & Production, 131(4), 30-32.

Bruno, J. (2019). How the IIoT can change business models. Manufacturing Engineering, 163(1), 12.

Digital Factories 2020: Shaping The Future Of Manufacturing, PwC DE., 2017 (PDF, 48 pp.)

Digital Product Development 2025: Agile, Collaborative, AI Driven and Customer Centric, PwC, 2020 (PDF, 45 pp.)

Enabling a digital and analytics transformation in heavy-industry manufacturing, McKinsey & Company, December 19, 2019

Governance and Management Economics, 7(2), 31-36.

Greenfield, D. (2019). Advice on scaling IIoT projects. ProFood World

Hayhoe, T., Podhorska, I., Siekelova, A., & Stehel, V. (2019). Sustainable manufacturing in industry 4.0: Cross-sector networks of multiple supply chains, cyber-physical production systems and AI-driven decision-making. Journal of Self

Kazuyuki, M. (2019). Digitalization of manufacturing process and open innovation: Survey results of small and medium-sized firms in japan. St. Louis: Federal Reserve Bank of St Louis.

‘Lighthouse’ manufacturers lead the way—can the rest of the world keep up? McKinsey & Company, January 7, 2019

Machine Learning in Manufacturing – Present and Future Use-Cases, Emerj Artificial Intelligence Research, last updated May 20, 2019, published by Jon Walker

Machine learning, AI are most impactful supply chain technologies. (2019). Material Handling & Logistics

Mapping heavy industry’s digital-manufacturing opportunities, McKinsey & Company, September 24, 2018

McKinsey, AI in production: A game changer for manufacturers with heavy assets, by Eleftherios Charalambous, Robert Feldmann, Gérard Richter and Christoph Schmitz

McKinsey, Digital Manufacturing – escaping pilot purgatory (PDF, 24 pp., no opt-in)

McKinsey, Driving Impact and Scale from Automation and AI, February 2019 (PDF, 100 pp., no opt-in).

McKinsey, ‘Lighthouse’ manufacturers, lead the way—can the rest of the world keep up? by Enno de Boer, Helena Leurent and Adrian Widmer; January, 2019.

McKinsey, Manufacturing: Analytics unleashes productivity and profitability, by Valerio Dilda, Lapo Mori, Olivier Noterdaeme and Christoph Schmitz, March, 2019

McKinsey/Harvard Business Review, Most of AI’s business uses will be in two areas,

Morey, B. (2019). Manufacturing and AI: Promises and pitfalls.<em> Manufacturing Engineering, 163(1), 10.

Preparing for the next normal via digital manufacturing’s scaling potential, McKinsey & Company, April 10, 2020

Reducing the barriers to entry in advanced analytics. (2019). Manufacturing.Net

Scaling AI in Manufacturing Operations: A Practitioners Perspective, Capgemini, January, 2020

Seven ways real-time monitoring is driving smart manufacturing. (2019). Manufacturing.Net,

Siemens, Next Level AI – Powered by Knowledge Graphs and Data Thinking, Siemens China Innovation Day, Michael May, Chengdu, May 15, 2019

Smartening up with Artificial Intelligence (AI) – What’s in it for Germany and its Industrial Sector?(52 pp., PDF, no opt-in) McKinsey Company.

Team predicts the useful life of batteries with data and AI. (2019, March 28). R & D.

The AI-powered enterprise: Unlocking the potential of AI at scale, Capgemini Research, July 2020

The Future of AI and Manufacturing, Microsoft, Greg Shaw (PDF, 73 pp., PDF, no opt-in).

The Rise of the AI-Powered Company in the Postcrisis World, Boston Consulting Group, April 2, 2020

Top 8 Data Science Use Cases in Manufacturing, ActiveWizards: A Machine Learning Company Igor Bobriakov, March 12, 2019

Walker, M. E. (2019). Armed with analytics: Manufacturing as a martial art. Industry Week

Wang, J., Ma, Y., Zhang, L., Gao, R. X., & Wu, D. (2018). Deep learning for smart manufacturing: Methods and applications. Journal of Manufacturing Systems, 48, 144–156.

Zulick, J. (2019). How machine learning is transforming industrial production. Machine Design.